Introduction

Essential to the Agile management of projects, the Kanban technique provides a fresh perspective on how to visualize and enhance the flow of labour. Although Kanban was developed in the context of lean production, it has now found widespread use outside of that sector. The ideas and practices of the Kanban technique are dissected in this article, along with the ways in which they enable teams to better visualize their work, organize their resources, and promote continuous development. By exploring the foundations of Kanban and its practical implementations, we can help in do my assignment and get better understand how it can be used as a flexible instrument for raising output, decreasing waste, and increasing responsiveness for different industries.

Discussion

Origin of Kanban and Principles

Japan finally found peace and prosperity in 1603. This was after a century of almost continual warfare and societal turmoil. A proliferation of stores and small enterprises lined the sidewalks of Japanese towns as the country’s economy boomed (Alaidaros et al., 2021). The word “Kanban” was coined in these same streets.

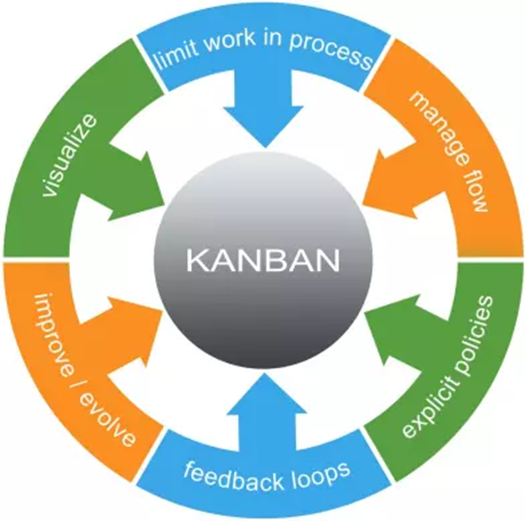

The principles are discussed below-

- Development is “invisible” until it’s finished. Therefore, a high-level overview of tasks is helpful for seeing how things are going. Kanban boards serve this purpose.

- Projects can be finished more quickly if the most critical tasks are prioritized, the workload of each team member is reduced, and they are finished before moving on to the next one (Vallon et al., 2019).

- Managing flow requires attention to the processes of labour rather than the workers who do them.

- Self-sufficiency, knowledge-sharing, and simplicity of onboarding are all boosted when documentation is clear and accessible.

- The team’s ability to interact with stakeholders and adapt to changing workflows with priorities is greatly enhanced through feedback loops, referred to as cadences.

- As a bonus, it boosts cooperation among the group.

Figure 1: Kanban Principles

Kanban Boards Workflow Visualization

Identification of the value stream

The goal of the mapping of value streams is to identify and describe all of the activities that contribute to the success of a project (Damij and Damij, 2021). No matter the procedure, write that essay and constantly be a set of steps that raise the value of a given object, paperwork, or material in its raw state in preparation for its eventual transformation into a finished good.

Identification of the Scope of Work

If the value flow is a road map, then people should identify and highlight the most often travelled route. Consider the extremely repeated processes in the value stream that keep certain teams interested and productive.

Mapping the Workflow Stages

Once the value stream plus its scope have been established, it is time to put items into a visual format. A board may be anything from a traditional whiteboard to an interactive Kanban board or even simply a blank wall in the workplace (Strickroth et al., 2022). Then, make it a table with columns, one for each step in the process from the left to the right. Identify each section by labelling the first column.

Defining the work types

When it is settled on a Kanban board design, the next step is to specify which categories of work will be processed by it.

Card template decision for each work

The next step is to establish what data is required and anticipated on a card for each task category (Omar et al., 2020). Because of the visual nature of Kanban boards, it is helpful to have a variety of card layouts for different types of work that may be used to emphasize and report on important information.

Placing work items

people should now be able to visualize the work because of their familiarity with card colours and layouts. Gather a deck of cards in a format people want, and then write each job on a different card.

Tracking workflow

Everyone will be able to observe bottlenecks, obstructions, and spots where the group is over-committed by tracking the state of workpieces as they progress through the procedure. This is why it’s so important to have the board in a common area.

Figure 2: Visualizing Workflow with Kanban

Waste Minimization

- Just-in-time techniques, which Kanban employs, stipulate that materials get to where they’re required “just in time” for utilization.

- Allowing the consumers to ‘pull’ the items through the manufacturing process is considerably more efficient than making them and expecting the buyers would purchase them, similar to using the just-in-time technique (Ali et al., 2020).

- Kanban’s emphasis on constant refinement is a key component in its ability to reduce waste.

- Kanban’s ability to reduce waste is largely attributable to the fact that it actively seeks any and all sources of waste in the procedure at hand (Leksic et al., 2019).

- Kanban’s performance may be attributed to the fact that it helps improve timing and workflow management, two factors that are crucial in every setting.

Diversifications of Kanban for Industries

Manufacturing: Since 1940, the concept of Kanban has seen widespread adoption across a broad range of sectors and production facilities all around the globe (Stauryla, 2021). Because of this, businesses have been able to boost output while also satisfying their clientele to a greater degree.

Software Development and IT: The Kanban approach has also seen widespread adoption in the information technology and software engineering sectors and make my assignment (Agarwal and Agarwal, 2020). The process helps these businesses in the early phases of new product development and throughout software development strategy planning.

Medical: Kanban might also be used in hospitals to determine how much of a certain medical device should be kept in stock. The goal is to reduce resource waste by keeping medical equipment inventory levels to a minimum while still meeting client needs.

Conclusion

If the most important activities are prioritized, the burden of everyone on the team is decreased, and each job is completed before going on to the next one, the project may be completed more rapidly utilizing the Kanban method. When a Kanban board layout is finalized, the following step is to define the types of tasks that will be handled by the board. The success of implementing Kanban can be traced back to the system’s ability to enhance timing and overall workflow management, two characteristics that are essential in every environment.

Reference

Agarwal, S. and Agarwal, A., 2020. Uses, Advantages and Opportunities of Kanban methods in Mechanical Engineering and Product Manufacturing. International Journal of Scientific and Research Publications (IJSRP), 10(1), p.p9704. https://www.academia.edu/download/63201599/ijsrp-p970420200505-47600-9mnc0e.pdf

Alaidaros, H., Omar, M. and Romli, R., 2021. The state of the art of agile kanban method: challenges and opportunities. Independent Journal of Management & Production, 12(8), pp.2535-2550. http://paulorodrigues.pro.br/ojs/ijmp/index.php/ijmp/article/download/1482/1945

Ali, S.A., Memon, Z.A., Sheikh, S.A. and Khan, M.H., 2020. Warehouse Management System and KANBAN Technique: A Review. http://www.estirj.com/Volume.4/No.1/3Ahsan41.pdf

Damij, N. and Damij, T., 2021. An approach to optimizing Kanban board workflow and shortening the project management plan. IEEE Transactions on Engineering Management. https://www.researchgate.net/profile/Talib-Damij/publication/356117092_An_Approach_to_Optimizing_Kanban_Board_Workflow_and_Shortening_the_Project_Management_Plan/links/62ee75110b37cc34477670a2/An-Approach-to-Optimizing-Kanban-Board-Workflow-and-Shortening-the-Project-Management-Plan.pdf

Leksic, I., Stefanic, N. and Veza, I., 2020. The impact of using different lean manufacturing tools on waste reduction. Advances in Production Engineering & Management, 15(1). http://www.apem-journal.org/Archives/2020/APEM15-1_081-092.pdf

Omar, M., Alaidaros, H. and Romli, R., 2020. An improved software project monitoring task model of Agile Kanban method: A practitioners’ perspective. International Journal on Advanced Science, Engineering and Information Technology, 10(2), pp.548-554. https://www.academia.edu/download/65985805/2285.pdf

Stauryla, E., 2021. KANBAN Implementation in Manufacturing Industries (Doctoral dissertation, Vilniaus Gedimino technikos universitetas). https://vb.vgtu.lt/object/elaba:97399829/97399829.pdf

Strickroth, S., Kreidenweis, M. and Wurm, Z., 2022, September. Learning from Agile Methods: Using a Kanban Board for Classroom Orchestration. In International Conference on Interactive Collaborative Learning (pp. 68-79). Cham: Springer International Publishing. https://www.tel.ifi.lmu.de/pubs/2022/icl/learning-from-agile-methods-using-a-kanban-board-for-classroom-orchestration.pdf

Vallon, R., Strobl, S., Ras, M., Bernhart, M. and Grechenig, T., 2019, May. Distributed Kanban with Limited Geographical Distance: Analyzing Lean Principles Pull, Work in Progress and Kaizen. In ENASE (pp. 210-217). https://www.scitepress.org/Papers/2019/76263/76263.pdf